- Home Page

- Company Profile

-

Our Products

- CNC Drilling Machine

- CNC Drilling Machine for Agriculture For Plough Manufacturing

- Automatic Mild Steel CNC Drilling Machine

- High Speed CNC Drilling Machine

- CNC Machine For Industrial Drilling

- CNC Automatic Drilling Machine

- CNC Plate sheet Drilling Machine

- CNC Drilling Machine

- Industrial CNC Drilling Machine

- 3 Axis CNC Drilling Machine

- Cnc Plate Sheet Drilling Machine

- CNC H Beam Drilling Machine

- CNC Tubesheet Drilling Machine

- High Speed CNC Tube Sheet Drilling Machine In Ahmedabad

- CNC Tube Sheet Drilling Machine Specially Designed For Industrial Drilling

- CNC Tube Drilling Machine

- CNC Tube Sheet Drilling Machine

- High Speed CNC Tube Sheet Drilling Machine

- CNC Tubesheet Drilling Machine

- Automatic CNC Tubesheet Drilling Machine

- Automatic CNC H Beam Drilling Machine

- Automatic CNC Drilling Machine

- CNC Drilling Machine

- Video and Certification

- Contact Us

Showroom

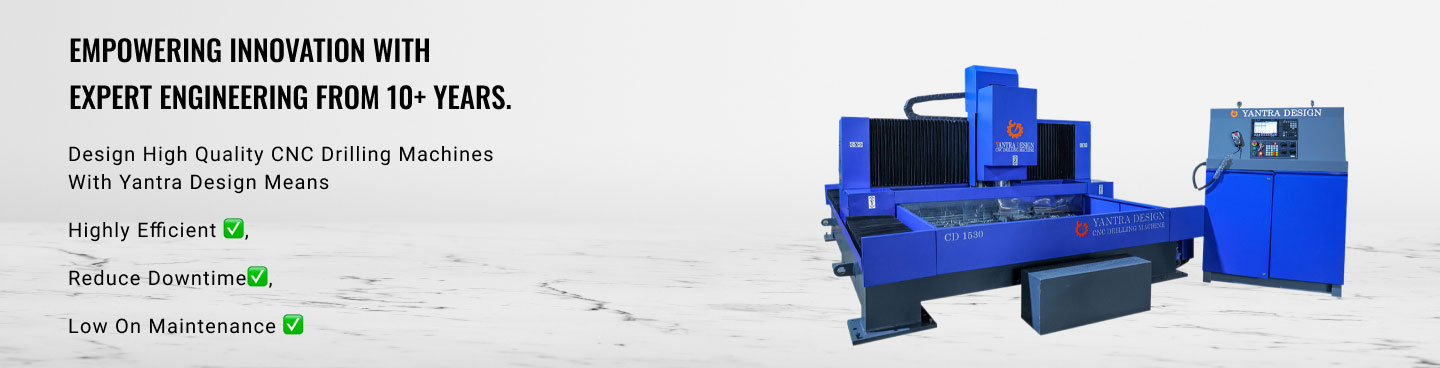

CNC Drilling Machines are well known for their high operating speed, excellent output and minimal noise generation. These energy efficient systems have user friendly operating interface to speed up their productivity.

"We Mainly Deal in Pune, Ahmedabad, Vadodara, Hyderabad, Mumbai, Surat, Chennai, Delhi, Thane, Rajkot, Bengaluru, Navi Mumbai, Nashik, Gurugram, Bhopal, Jamnagar, Jamshedpur, Ghaziabad, Lucknow, Ahmednagar, Coimbatore, Rajasthan, Jaipur, Bhiwandi, Faridabad, Indore, New Delhi, Sonipat, Greater Noida, Ludhiana, and Punjab."